Mr.E.Kumar, a Senior Section Engineer and Mr. S.Gunasekaran, a Technician at Coach Maintenance Depot, Basin Bridge proudly share that they go that extra mile to take care of ‘their families’ and ensure them safer journeys. By ‘their families’, they mean the passengers who are going to undertake journey in the coach that they are maintaining in the pitline. Pitline is an infrastructural requirement where tracks are laid with facility of pit for technical staff to undertake undergear examination of the coaches. Notwithstanding hot weather, rains and other vagaries of nature, the coach maintenance gang and pitline crew work round the clock. Every aspect of the coach working is thoroughly scrutinized and no defect goes unnoticed at the coaching depots. Working under Mechanical Department, their sole motto is to ensure proper maintenance of rolling stock with utmost care and dedication and ensuring clean exterior and interiors.

Southern Railway, presently has a holding of 6789 broad gauge Passenger coaches and 32 meter gauge MG Coaches. There are 19 Coach Maintenance Depots in Southern Railway functioning at Basin Bridge, Egmore Gopalswami Nagar, Tambaram, Erode, Coimbatore, Mettupalayam, Shoranur, Mangalore, Trivandrum, Kochuveli, Ernakulam, Nagercoil, Alleppey, Madurai, Tirunelveli, Tuticorin, Rameswaram, Tiruchchirappalli and Villupuram. There are 9 Wagon Maintenance Depots in Southern Railway. Average No.of wagon holding of Southern Railway is 9804 BG wagons.

Here is a brief insight into how the coach maintenance crew contribute for safe, reliable and punctual operation of trains:

An organised unit functions round the clock at railway stations, at enroute locations and at Coching Depots and Pitlines, keeping a vigilant eye on the running of the rolling stock to ensure safety. The staff possess in-depth knowledge of technical aspects pertaining to rolling stock.

Categorised as Senior Section Engineers(SSE), Junior Engineers(JE) and Artizans, the coaching depot staff work in gangs of ten or more and are led by Senior Section Engineers. SSEs are posted as In-charge of Depot, IOH Sheds, sickline/pitline, stores, Breal Down, Safety Inspectors, Carriage & Wagon Controllers in Control Offices, to mention a few.

Basically, coach maintenance is of five types, namely, Primary maintenance, Secondary maintenance, Turn around maintenance, Periodic Overhauling (POH) and Intermediate Overhauling (IOH) at defined interval.

Working in a pitline

Primary maintenance and secondary maintenance of full rake of train is done after it is placed on a pitline. Here in the pitline, the maintenance gang of Mechanical department undertake inspection, testing and attention of all the visual components both visually and using inspection gauge and tools to ensure safety of the whole train. They examine all the vital safety components like underframe & bogie components, running gear, suspension gear, buffer gear, brake gear etc., They also check the window shutter, fastenings, main door, toilet door, bio-toilets and all other toilet fittings. All the maintenance activities are done in accordance with the guidelines given in the coach maintenance manual issued by Railway Board. Exterior and interior washing of all coaches are also undertaken while the rake is placed in a pitline. Equipment like high pressure jet, scrubbing machine, vacuum cleaner, blower etc. are used for washing. To facilitate cleaning a catwalk arrangement similar to a platform is also made in a pitline.

On an average the coach maintenance crew complete the task of primary maintenance for a rake in 6 hours. Normally, a team of 15 depot staff will undertake the task of primary/secondary maintenance in a pitline.

Rolling-in & Rolling-out Examination

As you stand near the exit of the train coach for deboarding at your destination and as the train slowly meanders through to the platform , have you ever noticed a railway staff squatted on the ground and observing the wheels and other mechanical parts of the coaches. Yes, he is technician carrying out rolling in examination of the train. It involves looking out for dangling parts, hearing for any unusual sound, and see if anything is abnormal in the rolling stock and report the same for attention. Such rolling in examination is done at all major yards of the station on either side of the train. Rolling out examination is done while the train leaves the station. It is a critical activity in the safe running of trains.

Platform Maintenance

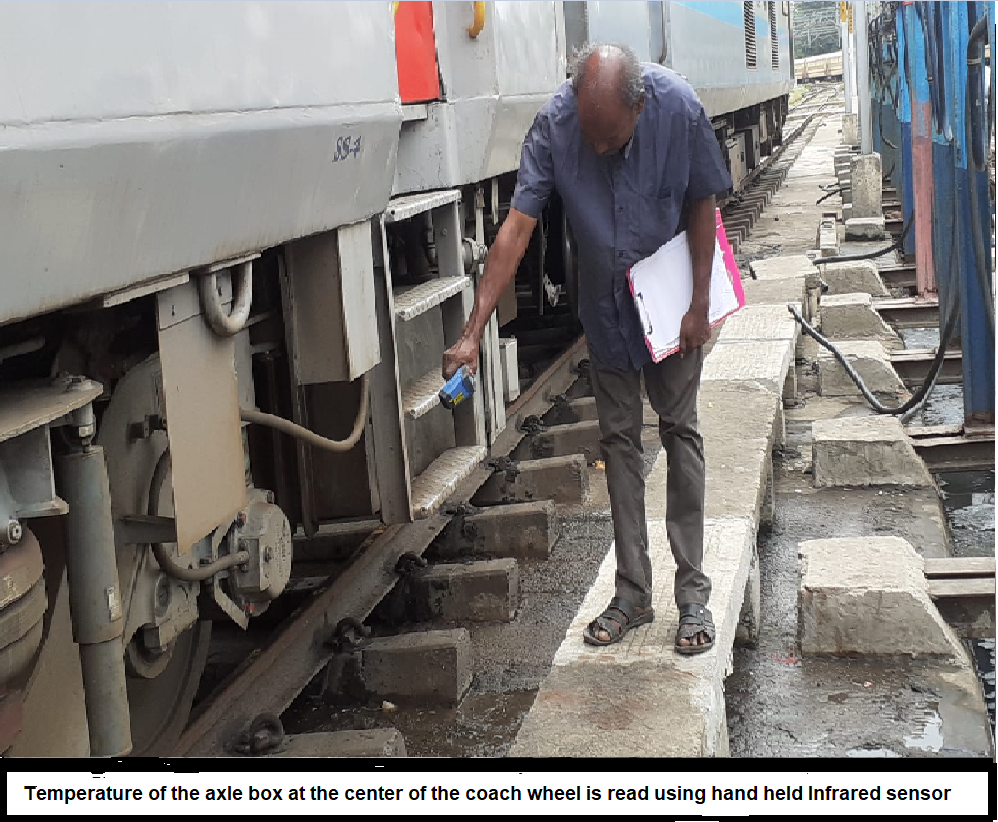

Immediately after the train has arrived at the platform, the technical staff of the mechanical department arduously carry out their assigned task. This includes axle box feeling wherein the temperature of the axle box at the center of the coach wheel is read using hand held Infrared thermometer and readings are recorded duly highlighting any abnormal reading for taking suitable action. While another team of staff manually pull the distributor valve’s release valve by kneeling down into the gap between platform and coach and another team gets engaged in watering all the coaches if the station is nominated for watering.

Thus, the mechanical staff of Southern Railway contribute immensely to safe running of trains by dutifully carrying out the tasks assigned to them either at the coaching depot pitlines or at the stations and their contribution is a testimony to Southern Railway’s continued focus on Passenger safety and comfort.